The typical plastic-based types of substrate used in the HP Designjet printers are much stronger than the typical Designjet paper-based substrates. Unlike paper media, the plastic media does not break when it is pulled.

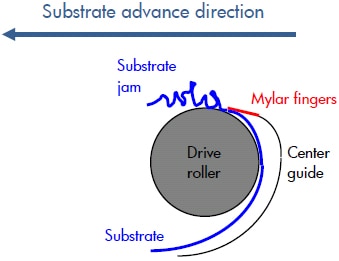

When a paper crash happens, either because the media is stuck in the paper path or because the carriage physically crashed against it, there is usually a bulk of substrate in the print zone. If this bulk of media is pulled, the media guide mylar "fingers" can be damaged. The following graph describes this.

Figure : A media crash occurs in the print zone

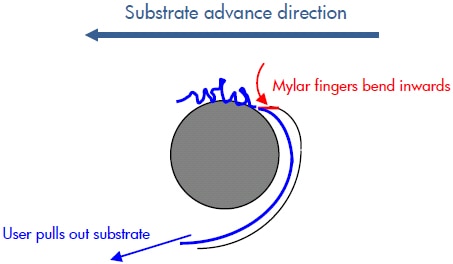

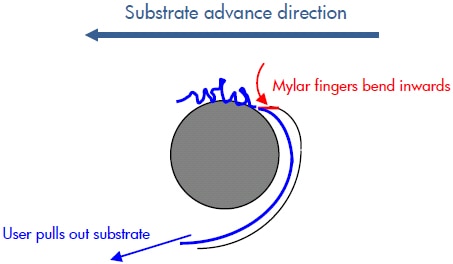

Figure : The customer tries removing the media jam by pulling it from the media input

When this is done, the media can catch the mylar fingers and bend them inward (toward the media input), as shown in the next image.

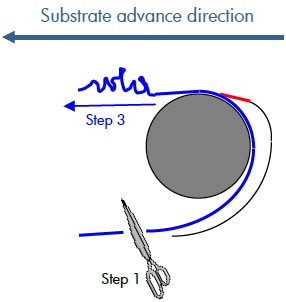

Figure : Mylar fingers are bent

This bent finger can sometimes damage the media in the subsequent prints, as the following picture shows.

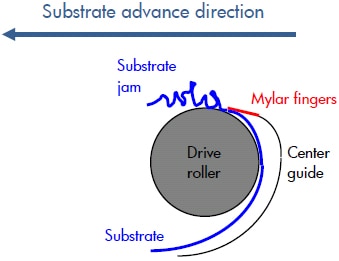

Figure : Damaged media from bent mylar fingers

A similar process can also damage the Media Sensor.